|

|

Equipment / Capabilities |

|

Equipment:

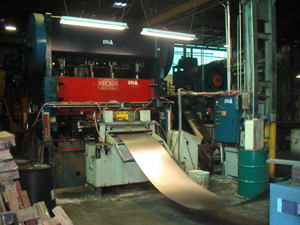

| PRESSES |

MACHINING |

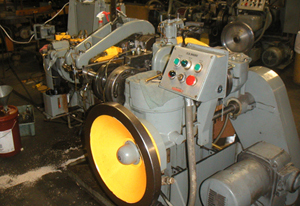

WIRE FORMING |

| Up to 300 Ton |

VMC up to 20x40 |

Multi-Slides |

| Max Bed 84x48 |

Bridgeport Mills |

Four-Slides |

| Servo Feeds 32"W |

NC Grinders |

Diacro Benders |

| Up to 120 spm |

NC Lathes |

Air Benders |

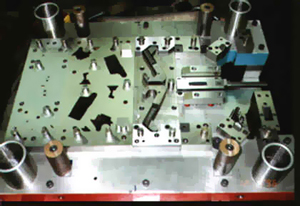

Dies In Use:

| Progressive |

Single Station |

Auto-Sensored |

| Blanking |

Compound |

In-Die Tapping |

| Draw |

Coin |

Rivet |

| Deep Draw |

Slide Form |

|

Additional Process Capabilities:

| Spot-Welding |

Tapping |

Deburring |

| Soldering |

Riveting |

Part Washing |

| MIG/TIG Welding |

Engraving |

Packaging |

Current Capabilities Thru Sub-Contract Partners:

| Zinc Plating |

E-Coat |

Heat-Treating |

| Hot Dip Galvanizing |

Epoxy Coating |

Austempering |

| Powder Coating |

Tin Plating |

Production Grinding |

| Chrome Plating |

Thread Rolling |

Laser Cutting |

Quality Assurance:

Acme uses computerized measuring equipment and standardized gauges to evaluate the integrity and stability of our processes and output. Statistical Process Controls are also available in order to meet a broad range of quality standards.

Engineering Assistance:Acme engineers, technicians, and craftsmen are available as an experienced resource for design and troubleshooting of experimental, prototype, and hard-to-build metal formed products. Computerized CAD and computerized indicators are at hand to assist our staff in product development.

Inventory Management & Lean Manufacturing

Extensive experience with KANBAN and other supplier process and pull systems.

|